Now Hiring: Sales Development Representative

September 20, 2023

PME Partners with Dr. Andrea Kealoha to Support Lahaina Research Initiative

January 29, 2024

Many researchers using Precision Measurement Engineering water quality monitoring devices will struggle with instances of fouling during their deployments. Fouling is the result of living organisms or non-living particles settling on external surfaces. Higher water temperatures during the summer season allow for more buildup, however, fouling can be a year-round issue when obtaining accurate data measurements. The buildup of organisms or particles can eventually block the sensors, resulting in inaccurate findings. PME developed effective options to combat fouling from occurring on their logging instruments.

Most fouling in relation to PME products is caused by living organisms growing on the sensors. The cause of fouling is the same in both freshwater and saltwater scenarios. Researchers must be aware that fouling organisms will vary based on their research location and application.

Lakes, or other freshwater locations have a wide range of significant fouling organisms. Loggers deployed in The Great Lakes may have fouling caused by zebra mussels, an invasive mollusk, whereas algae might be the problem in other lakes or bodies of fresh water. According to Dr. Mike Head, PME Founder, saltwater locations are similar in the variation of organisms, but temperature is a significant guiding factor. Higher temperatures are more appealing to fouling organisms looking for the perfect conditions to grow, meaning warmer water locations will see increased instances of fouling.

“Fouling is an issue all researchers collecting marine data need to be concerned about. While the causes of fouling can sometimes be unclear, it is not a problem that can be ignored. PME understands the importance of anti-fouling measures and is committed to helping their customers find the right products to prevent fouling,” says Dr. Mike Head.

Advancements in Anti-Fouling Technology

Numerous reviews have been conducted on fouling and its effects. A 2014 review from The Journal of Ocean Technology discusses antifouling technologies such as chemical coatings and non-toxic options. Chemical anti-fouling options can be problematic because they need to be effective without being harmful to researchers or marine ecosystems.

Robyn Gilden, Materials Manager at PME emphasizes the importance of working with engineers on creating custom parts and products. Every time PME develops a new product, Gilden looks closely at any modifications that need to be made based on case studies and customer feedback regarding fouling and works with engineers to accurately apply the modifications.

PME’s Anti-Fouling Solutions

PME offers a solution to prevent fouling with the WIPER. The WIPER is a self-contained, completely submersible, wiping device that can be used with a variety of sensors. The WIPER’s function is to clear any fouling organisms or particles from the device. The concept and look of the WIPERS are very similar for each PME product, yet there is slight variance in the wiping action due to factors such as sensor size.

“The WIPER brush, like a car windshield, swipes back and forth, removing debris. Users schedule the wiping frequency based on their fouling conditions. says Gilden.

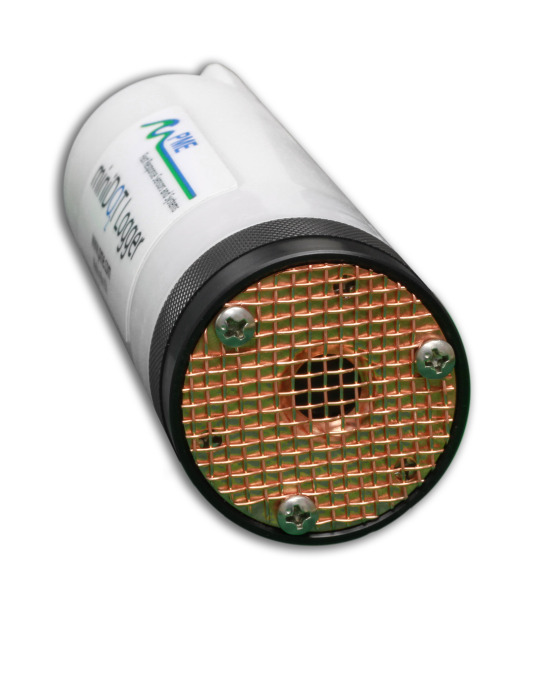

PME is currently providing the WIPER for the miniDOT® Logger, Cyclops-7 Logger and the miniPAR Logger, all of which work to reduce the growth of various organisms on the sensor. The WIPER can be programmed to wipe at various intervals and is powered from two AA Lithium batteries. A small brush rotates over the sensor to perform a complete wipe of the sensor surface, and then rests away from the sensor to allow for accurate and continuous monitoring.

Additional anti-fouling options are available for the miniDOT® Logger: A copper plate that fits directly on top of the sensor endcap and a copper mesh that creates a wire cage over the sensor. These anti-fouling add-ons can be used separately or together to increase WIPER effectiveness and longevity.

To learn more about PME’s WIPER and anti-fouling options, please contact our sales team.